Well Stimulation Services

Efficient and reliable stimulation solutions for enhanced well productivity.

Overview

Tailored Completions for Complex Wells

Tacrom’s Well Stimulation Services are designed to tackle the most complex well challenges, delivering tailored solutions that enhance productivity, extend reservoir life and minimize downtime.

With a proven track record of success across geothermal, gas storage, and conventional reservoirs, our services combine advanced equipment, such as pumps rated up to 20,000 HHP, with real-time monitoring systems to ensure precision and efficiency. Tacrom’s expertise is backed by over 900 successful frac jobs and extensive field experience across Europe, Ukraine, Kazakhstan and beyond. Our commitment to safety, sustainability and innovation makes us the trusted partner for achieving optimal well performance.

Services

Comprehensive Well Stimulation Services

Tacrom’s Well Stimulation Services are designed to enhance reservoir productivity, ensure well integrity, and overcome even the most complex challenges. With industry-leading expertise and cutting-edge equipment, we deliver High-Pressure Pumping for precision fracturing, Acid Pumping to dissolve formation blockages, Gravel-Pack Operations for effective sand control, Fluid Pumping for optimized flow dynamics and Chemical Solutions tailored to your specific well conditions.

High-Pressure Pumping

What we do

- Perform high-rate fracturing with advanced 20,000 HHP pumps for efficient proppant and fluid delivery.

- Use blender units capable of handling up to 16 m³/min to ensure precision in fluid and chemical mixing.

- Manage onshore and offshore operations with tailored solutions for geothermal, gas storage, and hydrocarbon wells.

Key Equipment

01

Frac Pumps

20,000 HHP Frac Pumps for high-pressure, high-volume operations

Pump Manifold Trailers

10-Frac Pump Manifold Trailers for multi-pump configurations

Blender Units

16 m³/min Blender Units for real-time mixing and control of chemicals and fluids

Acid Pumping

What we do

- Deliver precise matrix acidizing treatments to dissolve formation blockages and enhance permeability.

- Utilize corrosion-resistant tools and advanced acid inhibitors to protect equipment and extend operational life.

- Provide real-time monitoring to optimize acid placement and ensure treatment efficiency.

Key Equipment

02

Acid Pump Units

320 HHP Acid Pump Units with flow rates of 30–750 l/min, ideal for matrix acidizing

Chemical Tanks

Up to 900 liters, allowing continuous acid mixing and injection during operations

Gravel-Pack Operations

What we do

- Stabilize wellbore integrity and prevent sand production through high-precision gravel packing techniques.

- Deliver resin-based chemical treatments for sand consolidation, ensuring long-term well stability.

- Utilize advanced proppant delivery systems for consistent gravel placement.

Key Equipment

03

Gravel Pack Pump Units

Capable of flow rates up to 800 l/min, designed for efficient gravel placement

Sand King Units

150 MT capacity for large-scale proppant storage and delivery

Mixing and Auger Systems

Ensure uniform proppant distribution during gravel pack applications

Fluid Pumping

What we do

- Offer tailored fluid solutions, including slickwater, hybrid systems, and chemical blends to optimize flow and reduce formation damage.

- Manage fluid preparation, mixing, and pumping in real-time to ensure compatibility with well conditions.

- Perform detailed laboratory testing for fluid compatibility and effectiveness.

Key Equipment

04

Hydration Units

Capable of blending and pumping up to 8 m³/min, with real-time monitoring of chemical rates

Trailer-Mounted Chemical Units

Equipped with five 900-liter stainless steel tanks for precise on-the-fly chemical mixing

Chemical Solutions

What we do

- Provide custom chemical solutions to tackle wax, scale, and other production challenges.

- Develop and apply specialized additives such as friction reducers, biocides, and stabilizers.

- Perform laboratory testing to ensure chemical compatibility with specific reservoir conditions.

Key Equipment

05

Data Management Systems

Enable real-time monitoring and optimization of chemical application

Proprietary Chemical Blends

Designed to enhance flow efficiency and tackle reservoir-specific challenges

Why Tacrom

Your Trusted Stimulation Partner

Proven Expertise

With over 900 frac jobs, 800 gravel packs and countless acid and fluid pumping operations, our track record speaks for itself.

Advanced Equipment

Cutting-edge technology, including 20,000 HHP frac pumps, gravel-pack units and real-time data monitoring systems, ensuring accurate, efficient and safe operations.

Global Presence

Our teams operate across Europe, Ukraine, Kazakhstan and beyond, offering rapid mobilization and local expertise for any stimulation project.

Sustainability Commitment

Tacrom’s ESG-driven approach ensures environmentally conscious practices aligned with global safety and environmental standards.

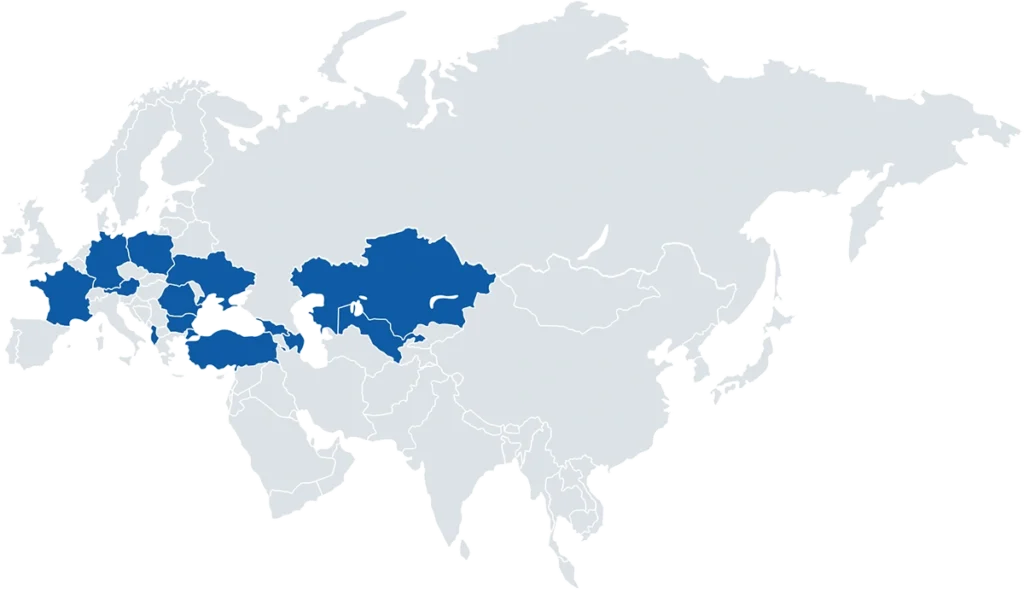

Worldwide Expertise

Geographical Reach

Expanding Expertise Across Europe and Beyond

Tacrom is headquartered in Ploiesti, Romania. Other offices/bases are located in Celle (Germany), Poltava and Kiev (Ukraine) and Qarshi (Uzbekistan). Tacrom has worked in countries from France in the West to Turkmenistan & India in the East.

France

Germany

Romania

Ukraine

Turkey

Kazakhstan

Poland

Uzbekistan

Bulgaria

Austria

Albania

Georgia

Azerbaijan

Other